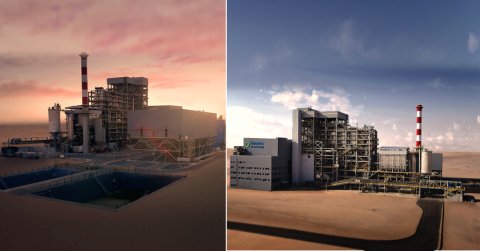

The Sharjah Waste to Energy plant, a first of its kind project in the Middle East, has achieved multiple landmark milestones since its inauguration a year ago. Tied to the Sharjah electrical grid, the plant has generated enough energy to power over 2,000 homes per year while offsetting 150,000 tons of CO2 emissions.

Around 60 percent of greenhouse gas emissions in the UAE come from household and industrial waste decomposing in landfills. Since inauguration, the plant has processed over 100,000 tonnes of waste, equivalent to the waste produced by 180,000 people per year and recovered over 250 tonnes of metal during its operations. As a result, Sharjah has achieved a new record in its zero-waste to landfill journey, achieving a waste diversion rate of 90 percent.

Inaugurated in May 2022, the Sharjah Waste to Energy plant is a project of the Emirates Waste to Energy joint venture between BEEAH Group, the Middle East’s sustainability pioneer, and Masdar, one of the world’s leading clean energy companies.

Speaking on the development, Khaled Al Huraimel, Group CEO of BEEAH Group, said: “The Sharjah Waste to Energy plant is an example of successful collaboration towards the UAE’s sustainability agenda. In partnership with Masdar, we have pioneered a waste-to-energy innovation that adds to the national clean energy mix, while also accelerating towards our zero-waste to landfill targets in Sharjah. We have also achieved 90 percent landfill waste diversion, a new record for the Middle East, which highlights the positive impact energy innovations can have for sustainable waste management. The Sharjah Waste to Energy plant demonstrates how clean energy can not only help meet energy demand, but also recover valuable material and tackle the mounting challenge of waste in growing cities across the Middle East”.

The plant is ramping up operations to produce 30 MW of power annually, while processing 300,000 tonnes of waste that would otherwise go to landfill. Over a 12-month period, the plant is capable of offsetting 450,000 tonnes of CO2.

Mohamed Jameel Al Ramahi, CEO of Masdar, said: “Achieving the landmark of 100,000 tonnes of waste processed within the first year of operation is a fantastic milestone on our journey towards pioneering worldwide efforts towards decarbonisation. Utilising the latest innovative technologies, the plant has played a leading role in Sharjah’s 90 percent landfill waste diversion success and in supporting the UAE’s goal of diverting 75 percent of solid waste from landfills. We look forward to boosting R&D investment in waste-to-energy projects and working with BEEAH to further accelerate the reduction of global carbon emissions and divert waste from landfills”.

Located in the Al Sajaa area of Sharjah, the Sharjah Waste to Energy plant is adjacent to BEEAH’s integrated waste management complex, where recycling facilities are also enabling higher rates of landfill waste diversion.

The Sharjah Waste to Energy plant incinerates waste, producing a flue gas that is treated in line with European Union environmental standards. Heat produced during the process is recovered and used in a steam boiler which, in turn, is used to run an electrical turbine and produce electricity. The plant’s boiler and thermal efficiency rates are among the highest in the industry.

In December last year, BEEAH and Masdar partnered with Veolia Near & Middle East to operate and maintain the waste to energy plant for a period of 25 years following international best practices. So far, the plant has treated 463 million m3 of air, enough to fill the Burj Khalifa 255 times over.

The Sharjah Waste to Energy plant is the first project of the Emirates Waste to Energy joint venture between BEEAH and Masdar. The joint venture is pursuing the launch of more waste-to-energy plants in the UAE and the wider region to pioneer integrated solutions for zero-waste to landfill and net-zero emissions.